Injection moulding & cosmetic finishing

"WE DEVELOP OUR OWN MULTI-AXIS"

Since our humble beginnings with only two machines in 1974, SKP now has more than 250 injection moulding machines ranging from from 50 to 2,000 tons to cater to our clients' every requirement. Utilising top industrial names such as Toshiba Machine, Haitian, Nissei P, and Demag, SKP's renowned automation and precision in mould design and fabrication extends to our close-tolerance injection moulding processes which feature double-injection machines, multi-cavity moulds, and even in-mould label moulding.

To further add value to our seamless, one-stop supply chain, SKP provides advanced secondary operations for the perfect cosmetic finish to your plastic components. Widely acclaimed and recognised by our clients, SKP's post-moulding processes feature 10k Class clean room facilities, high-gloss finish coatings, ultrasonic welding, and fully-automated multi-colour tempo printing.

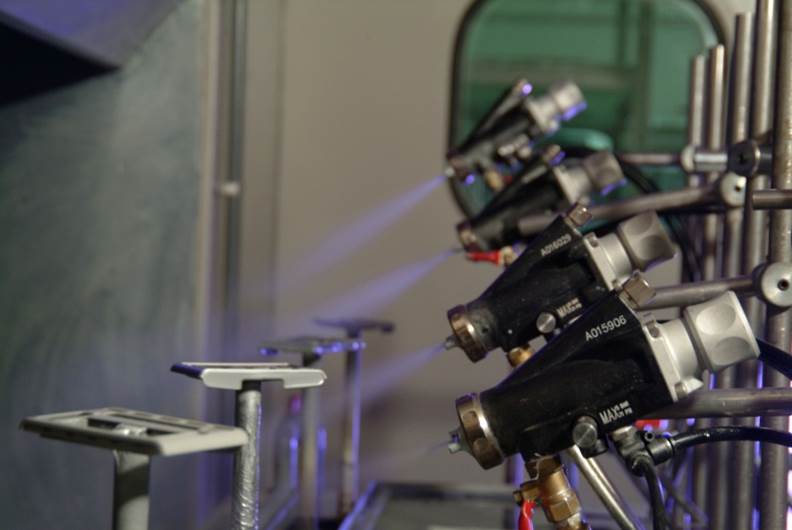

So dedicated are we to the ideal finish of your plastic components that we have developed our own multi-axis, CNC-programmable gantry robots from a team of dedicated in-house robotics engineers that make us a leader in the region.

Our injection moulding capabilities

- Mould design and fabrication

- Full automation

- High capacity moulding from 50 tons to 2,000 tons

- Double-injection machines

- Multi-cavity moulds

- Heat & cool systems

- E-Moulding systems

- Auto-insert moulding

- In-mould label moulding

- High-speed, thin-wall moulding

Our cosmetic finishing capabilities

- 10k Class clean room facilities

- Internally-developed, multi-axis gantry robot (CNC programmable)

- High-gloss finish coating (2 coats, base and top coat)

- Spindle spray systems

- Water-based systems

- PU/Rubber paint capability

- Automated multi-colour tempo printing

- Rotational pad printing

- Silk-screen printing

- UV coating

- Hot stamping facilities

- Ultrasonic welding

- Heat staking

End to End Services to Choose From

- 2K Air Conditioned Room

- UV Coating

- Spindle System

- Robotic Arm System

- Multi Axis Gantry Robot

- Water based System

- High Gloss Finish Coating

- PU / Rubber Paint

- Automated Multi Color Tempo Printing

- Silk Screen Printing

- Hot Stamping Facilities

- Ultrasonic Welding

- Heat Staking